At Talisen Construction, we understand that successful healthcare imaging construction projects involve more than just technical know-how. Navigating these projects presents challenges that extend well beyond standard construction tasks. Imaging equipment installations require utmost precision—not only in ensuring the structural soundness of the space but also in the seamless integration of sophisticated electrical and mechanical systems. Moreover, maintaining strict compliance with health codes while keeping patient care uninterrupted adds yet another layer of complexity.

In this blog post, we’ll explore the essential components of medical imaging equipment projects and how our team at Talisen consistently meets these challenges. From managing tight schedules to navigating complex health code requirements, we’ll demonstrate how our blend of expertise, precision, and problem-solving turns intricate projects into success stories for our healthcare clients. Join us as we take a closer look at how Talisen faces these projects head-on:

Precision in Structural Requirements

Weight, Vibration & Noise

When installing imaging devices, careful attention must be paid to factors like weight, vibration, and noise. Consider MRI machines as an example; these large-scale imaging machines can weigh anywhere from 6,000 to over 80,000 pounds. Alongside their considerable size, MRI machines produce intense vibrations due to their rapidly changing magnetic fields and gradient coils, which can result in noise levels reaching up to 120 decibels during operation. If not properly controlled, these vibrations can negatively affect image quality, calibration, and accuracy, and the high noise levels can create a disturbing environment for both patients and staff.

New 1.5T MRI Scanner at CUIMC’s ColumbiaDoctors Tarrytown location.

Considering these factors, a successful MRI machine installation requires an experienced team that understands everything at stake in a healthcare setting. Talisen’s 15 years of healthcare construction expertise emphasizes the importance of performing detailed structural analyses with every imaging suit project. We prioritize stable foundations, level flooring, proper structural reinforcements, and advanced soundproofing, successfully retrofitting or reinforcing existing structures to safely support valuable diagnostic equipment. Our solutions assure the safety and stability of the equipment and create a quieter and more agreeable environment for patients and staff.

Understanding that even minor vibrations can affect imaging quality, our team employs precise engineering solutions to stabilize the equipment, utilizing vibration isolation pads and constructing separate foundations when necessary. Talisen also implements advanced soundproofing measures that address the noise generated by various radiology equipment, integrating state-of-the-art acoustic panels and sound-dampening materials to minimize noise disruption within the imaging suite and throughout the facility.

Shielding Requirements

Most diagnostic imaging machines require specialized shielding to protect against radiation exposure and electromagnetic interference, for instance:

- MRI machines use powerful magnetic fields and radio frequency (RF) waves that are sensitive to external EMI. Specialized RF shielding or Faraday cages block external EMI, prevent interference with the MRI’s imaging capabilities, contain the magnetic field, and protect nearby electronic devices and medical equipment.

- X-ray machines and CT scanners emit harmful ionizing radiation. Lead-lined walls, doors, and glass, as well as specialized barriers and protective equipment, shield healthcare workers and patients from radiation exposure during procedures. Specialized shielding also prevents radiation from affecting other areas of the building.

- PET/CT scanners and LINACs require extensive lead and concrete shielding from high-energy X-rays and electrons generated during treatments.

- Copper shielding protects MRI suites from radio frequency (RF) waves.

- These RF waves can interfere with equipment and distort imaging.

- Comprehensive shielding is a key component of Talisen’s medical imaging projects.

When installing imaging equipment, each modality demands a unique approach to shielding, depending on the specific radiation levels or electromagnetic fields involved. At Talisen, we take these requirements seriously, implementing various protective measures, including lead-lined walls, floors, and ceilings. We also use copper shielding and Faraday cages for more complex needs. Our commitment to these rigorous safety standards ensures that patients, healthcare staff, and sensitive medical equipment remain protected.

Ceiling Height Considerations

Another factor to consider during an imaging installation project is the building’s ceiling height. While most CT scanners typically fit in rooms with standard ceilings, MRI machines and LINACs tend to require higher-than-average ceiling heights to accommodate the machines’ bores and associated gantries. Similarly, specific C-arm X-ray systems may need higher ceilings to give the equipment a full range of motion. At the same time, PET/CT scanners sometimes require extra space for necessary overhead infrastructure.

Raising the ceiling in older or repurposed buildings often requires extensive structural modifications beyond your typical renovation efforts. At Talisen, our team is adept at making structural modifications that accommodate imaging equipment in spaces with limited ceiling heights. These modifications, which can include optimizing the layout to accommodate the machine’s components, are needs that our project managers anticipate early in the project, thereby minimizing delays and guaranteeing a flawless installation.

- MRI machines tend to require higher-than-average ceiling heights to accommodate the machines’ bores and associated gantries.

Learn more about how Talisen’s construction approach saves you time and money.

Complex Electrical & Mechanical Systems

Power Supply Needs

Medical imaging equipment demands a robust electrical infrastructure. For example, MRI machines call for high-capacity electrical systems that can handle the equipment’s energy consumption, often necessitating dedicated transformers and backup generators. Coordinating this with existing power systems can be complex, but Talisen addresses these electrical demands with skill and meticulous planning. Recognizing the high-capacity electrical systems required for such devices, we ensure the ideal integration of reliable transformers and backup generators to manage substantial energy consumption. We also collaborate closely with engineers and electrical contractors to assess the existing power infrastructure and design tailored solutions that support the increased load without compromising the structure’s overall electrical integrity.

Additionally, our team utilizes advanced Building Information Modeling (BIM) and thorough pre-construction planning to coordinate the new systems with minimal disruption to ongoing operations, ensuring that the imaging equipment and the healthcare facility function efficiently and safely.

Specialized Cooling Systems

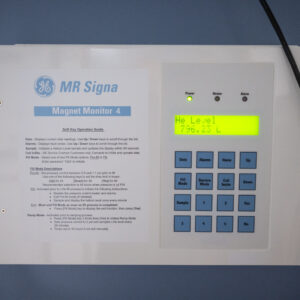

Powerful medical imaging devices call for specialized cooling systems capable of mitigating the high heat levels these machines generate. In healthcare settings, where equipment reliability and patient safety are paramount, specialized cooling systems must be carefully designed, installed, and maintained to prevent overheating that could lead to costly downtime or safety risks for patients and staff. However, properly installing these systems requires deep technical knowledge and precise execution. MRI machines specifically utilize superconducting magnets that require cryogenic cooling systems, typically involving liquid helium, to maintain the extremely low temperatures needed for optimal magnetic performance. Without such cooling, these magnets could lose their superconducting properties, leading to equipment failure and costly repairs.

Talisen understands the unique demands of medical environments and excels in integrating specialized imaging cooling systems into complex healthcare builds. Our expertise guarantees correct and efficient cooling system installation that provides clients with reliable and high-performing imaging technology.

Logistical Challenges

Delivering & Installing Equipment

The sheer size and weight of medical imaging machines present logistical challenges for delivering and installing the equipment. Hospitals and medical centers often have limited space and require precise coordination to avoid disruptions to ongoing patient care, meaning construction teams must manage tight access points while ensuring they do not interfere with ongoing operations.

One such example is Talisen Construction’s recent MRI suite expansion and renovation project at ColumbiaDoctors Tarrytown, where we partnered with Columbia University Irving Medical Center (CUIMC) to renovate and expand the MRI suite to accommodate a new state-of-the-art 1.5T MRI scanner. This project, which spanned approximately 930 gross square feet, involved renovating existing spaces within the imaging department and expanding the MRI control room.

The complexity of integrating the new MRI scanner with the existing 3T MRI suite without disrupting ongoing operations was a key challenge that Talisen successfully navigated through meticulous planning and coordination. Our team utilized an existing rigging path, upgraded infrastructure with a dedicated cryogen vent, chiller, and electrical feed, and extended the MRI slab to comply with Department of Health requirements—all while ensuring minimal impact on the facility’s day-to-day activities.

Talisen Construction works closely with healthcare staff and building managers to ensure your medical imaging installation project does not interfere with ongoing operations or impact patient care. Our team takes every measure to minimize potential disruptions and maintain the integrity of your facility, such as meticulously mapping out delivery routes, utilizing cranes and knockout walls, and temporarily disassembling equipment to navigate tight access points.

Health Code Compliance

Medical imaging device projects must adhere to all local health codes with a particular focus on infection control standards. Talisen Construction is dedicated to not only meeting but exceeding these stringent requirements by employing rigorous infection control protocols. We implement state-of-the-art dust and debris containment systems that prioritize patient safety and maintain high operational standards throughout construction, allowing your healthcare facility to remain fully functional and compliant during every project phase.

Stakeholder Collaboration

Collaboration with healthcare professionals, building managers, and equipment manufacturers is essential to certify that imaging equipment projects meet the specific needs of the medical team. Talisen strongly emphasizes pre-construction meetings, mock-ups, and rigorous testing, making sure all stakeholders are aligned and the imaging equipment functions optimally within the designed space.

Project Timeline & Budget Considerations

Healthcare projects often operate under tight deadlines, as facilities need to maintain or expand their service offerings. Delays can have significant financial and operational impacts, so construction teams must work efficiently while maintaining quality and safety benchmarks. The cost of installing complex imaging equipment can be substantial, and construction teams must carefully manage the budget to avoid cost overruns. Talisen understands the critical nature of healthcare projects and the need to adhere to tight timelines. Our team’s expertise in diligent planning, value engineering, and close coordination with suppliers and subcontractors avoids cost overruns and ensures all aspects of the project are accounted for.

Conclusion

Installing imaging equipment in healthcare facilities requires a specialized approach that balances technical mastery, logistical coordination, and regulatory compliance. Talisen Construction executes medical imaging equipment construction projects masterfully, focusing on patient safety, operational integrity, and project efficiency. From structural reinforcements and advanced soundproofing to specialized shielding and complex electrical systems, our team expertly manages every aspect of installation. Healthcare facilities partnering with Talisen can trust that we will complete their imaging projects efficiently, cost-effectively, and with exceptional quality and safety.

Elevate your healthcare facility with precision—reach out to Talisen today to ensure your medical imaging equipment installation is seamless, efficient, and up to code. Let’s build the future of healthcare together.